Project Brief

The scheme involved the installation of a three-storey mezzanine floor structure, within an existing Next Automated Returned Items – Storage and Picking System warehouse. The mezzanine sits above a congested marshalling area and loading dock containing numerous conveyor lines.

The project also delivered a two-storey steel frame extension, adjacent to the existing warehouse gable.

The main function of the warehouse is the return of mail-order items. It was imperative that the conveyors remained operational, on a 24 hour a day basis, throughout the delivery of the works.

Solution

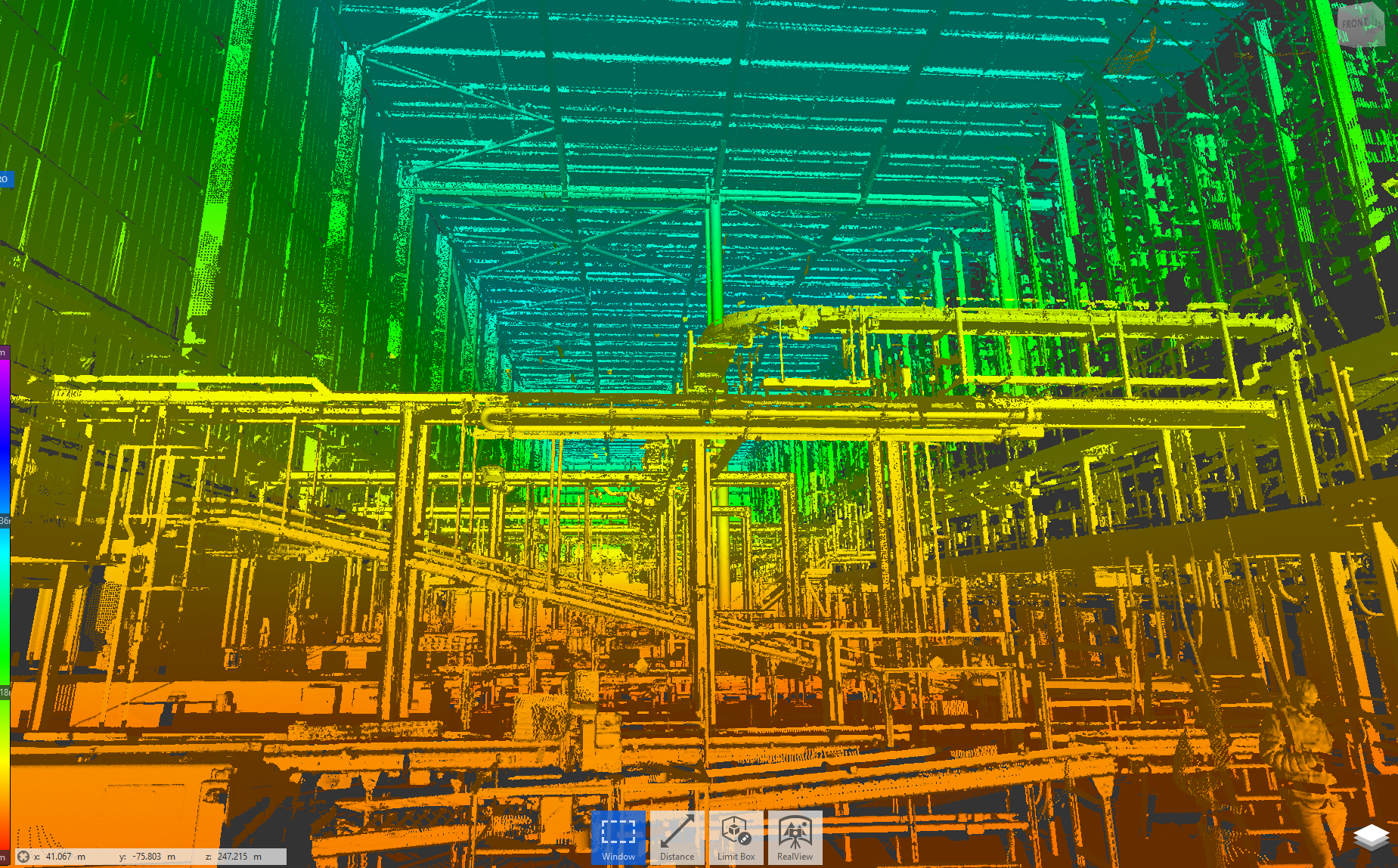

The existing building was surveyed using our FARO 3D laser point cloud scanner. This information enabled our engineers to quickly evaluate the viability of a new extension and aid structural design calculations. The extension was modelled in Revit software to produce a BIM model of the proposed design.

We used laser scanning to evaluate the viability and engineering constraints of an extension within a working high bay warehouse automated processing plant. The results guided engineering decision making throughout the development process. The point cloud was made particularly accessible with Virtual Reality technology to allow full immersion without being present on site. The point cloud of the internal structure allowed us to carefully co-ordinate the design of new mezzanines which were modelled in Revit around the existing building fabric.

The corner building section was modelled using a steel mezzanine design. The mezzanine structure had to support 400 racking legs across its area – a large number of point loads and load combinations had to be included within the analysis model. Each individual rack was supported by a steelwork bracket welded to a support beam. The rack bases required careful grouting using epoxy resin to uniform pressure distribution between the racking base plate and the support bracket.

The mezzanine structure and extension were built in parallel – two separate design teams were therefore involved. Adept demonstrated excellent collaboration to ensure that both teams had timely and accurate information in order to progress the works efficiently.